We use cookies to analyze traffic and improve your experience. We may also share your information with our analytics partners to improve our website, as detailed in our Privacy Policy. You consent to our cookies if you continue to use this website.

The American wind industry is rapidly growing. Recently passed government legislation, including the Inflation Reduction Act (IRA), provides tax credits and incentives for wind energy projects. This has led to an increase in structural steel plate demand as wind farm projects, both onshore and offshore, get underway.

In this article, we will explore the properties and applications of steel plate grades that are commonly used in wind turbines.

The mechanical and chemical properties of steel plate used in the wind industry are dictated by one of two different standardization organizations: EN standards and ASTM. Standards set by these organizations help to ensure that materials used in wind turbines can withstand harsh conditions without corroding or becoming brittle, especially in colder temperatures.

Since wind energy technology became widespread in Europe before it was utilized in the U.S., wind turbine models are typically designed to EN standards. However, as wind energy projects grew in the U.S., ASTM identified EN grades that have similar chemical and mechanical properties to allow for substitution amid growing demand.

Next, we will discuss the steel plate grades commonly used in wind industry applications. ASTM 572-50 and EN S355 are two high strength low alloy (HSLA) grades with chemical compositions that are ideal for use in wind turbines. We will explore these properties in more depth below.

ASTM A572-50 is a popular HSLA grade with mechanical properties that enable it to be used in harsh outdoor conditions. Onshore and offshore wind turbines alike use A572-50, as the material is lightweight and simple to shape while still maintaining the ability to bear great stresses and loads.

|

Chemical |

Composition |

Benefit for Wind Application |

|

Carbon Max |

0.23% |

Help maintain lightweight properties |

|

Manganese Max |

1.35% |

Decreases brittleness and impacts strength |

|

Phosphorus Max |

0.030% |

Strengthens low carbon steel, increases resistance to corrosion and improves machinability |

|

Sulfur Max |

0.030% |

Improves machinability |

|

Silicon to 1 ½” Thick Max |

0.40% |

Outstanding weathering properties (i.e., Temperature resistant, durability) |

|

Silicon Over 1 ½” Thick |

0.15 – 0.40% |

Outstanding weathering properties (i.e., Temperature resistant, durability) |

EN S355 is an HSLA grade used to build EN standard wind turbines. With similar chemical and mechanical properties to A572-50, this material is ideal for use in wind turbines that are regularly exposed to harsh conditions.

The customer’s Technical Purchase Specification (TPS) dictates the steel grade required for each application. In addition to the grade required, there may be additional call outs for impact toughness, commonly referred to as Charpy Impacts, or CVN. For ASTM grade material, the CVN is typically spelled out within the TPS based on thickness and grade. For EN grade material, the CVN requirement is indicated by the letters proceeding the grade. For example, S355-J2 indicates the grade, S355, and the impact required is referenced with the “J2” designation.

For example, EN S355-J2 indicates that the material can maintain a toughness of 27 Jules and withstand temperatures up to -20 degrees Celsius without failing.

|

TPS Requirement |

Charpy V-Notch Impact Max |

|

JR |

27J, 20 Degrees Celsius |

|

J0 |

27J, 0 Degrees Celsius |

|

J2 |

27J, -20 Degrees Celsius |

|

K2 |

40J, -20 Degrees Celsius |

|

NL |

27J, -50 Degrees Celsius |

|

ML |

27J, -50 Degrees Celsius |

While the use of wind turbines is growing in the U.S., fabricators often struggle when it comes to deciphering EN standards for a wind turbine project.

Wind turbines have been utilized in Europe far longer and more frequently than in the U.S. Because of this, EN standards are commonplace in the wind industry, which can be difficult for U.S. fabricators to understand due to differences in European measurements and terminology.

Another complication with EN standards is the need for U.S. steel producers to be EN certified to produce EN grade material.

While there are limited resources available to help fabricators understand EN standards, steel suppliers like Leeco are very familiar with EN grades and can work with fabricators to ensure that they understand their project’s materials requirements.

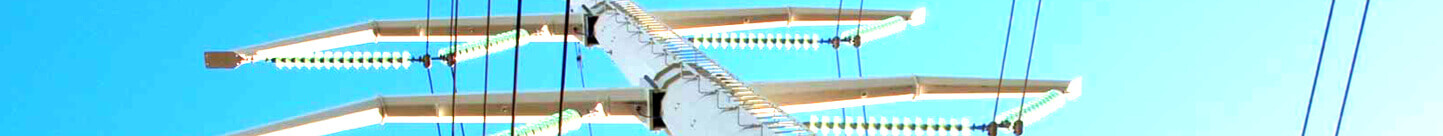

Now, we will discuss the specific applications of steel plate within wind turbines. These applications can differ depending on whether a wind turbine is onshore or offshore.

While onshore wind turbines experience different wind patterns and elements than offshore wind turbines, strength and temperature tolerance are important mechanical properties to ensuring the longevity of the wind turbine.

Steel plate is used in several key pieces of the wind turbine’s structure, including:

An onshore wind turbine primarily uses steel in the tower, as it is made of shell plates. Depending on the wind turbine’s size, a turbine’s total mass can contain anywhere from 66 – 79% of steel.

Offshore wind turbines, while the same in overall structure, have several key differences from onshore turbines.

The first key difference is the wear on the material itself. Offshore wind turbines are exposed to different and harsher environmental factors than onshore wind turbines, which can cause early erosion and malfunction. These factors include stronger and more irregular wind patterns. Elements that reduce corrosion are added to materials used in offshore turbines as needed to combat these harsh conditions.

The parts of an offshore turbine that utilize steel plate are the same as an onshore turbine with one major distinction: the foundation. Known as a “monopile”, the foundation of an offshore wind turbine is located under water and made also of steel plate. The total amount of steel needed to construct a monopile can amount to 2,500 tons of steel, depending on the depth of the water in which it is being constructed.

Steel used to construct wind turbines must undergo testing to ensure that it can endure harsh conditions. The Charpy Impact Test, also known as the Charpy V-Notch Test, is the standardized test done on steel used for wind turbines.

The Charpy Impact Test measures a material's ability to absorb energy, or impact, within a given temperature range.

Brittle materials can absorb less impact before fracturing, and colder temperatures increase brittleness. For projects that require steel material exposed to cold temperatures, like wind turbines, the Charpy test helps ensure engineers the metal will withstand the expected harsh conditions.

The Charpy test pits a small piece of test material against a heavy pendulum hammer with a V-shaped notch in the middle. The pendulum swings into the test piece, and the absorbed energy is measured.

Steel for all wind turbines must withstand a minimum of 27 Jules of force. However, this requirement changes depending on the climate the wind turbine is in. Each OEM’s requirement is specified in their unique Technical Purchase Specification (TPS). Requirements typically range from -50 Degrees Celsius to +20 Degrees Celsius to accommodate various weather conditions. As turbines become increasingly taller, the need for materials to withstand different atmospheric elements, such as temperature, will need to be modified.

Once any necessary material tests are done, some fabricators may request processing services. While many require just the raw steel plate, some require shapes and complex parts cut to their exact dimensions. The processes done to create these parts include:

Collaborating with a steel plate supplier that is knowledgeable about the wind industry is essential to the completion of your project.

At Leeco, we have the expertise to help fulfill your order in a timely manner. The benefits of working with Leeco include:

Contact us or request a quote today to discuss your wind industry steel plate needs.

Looking for a quote? We recommend you use our quote builder or submit a request for quote document via our RFQ Form.

Quote Builder Submit an RFQ