We use cookies to analyze traffic and improve your experience. We may also share your information with our analytics partners to improve our website, as detailed in our Privacy Policy. You consent to our cookies if you continue to use this website.

Certain applications – such as infrastructure projects or the manufacturing of construction equipment – require thicker steel plate material known as heavy steel plate. Heavy plate is used in various sectors where the material must withstand greater forces than is typically required.

This article will provide an overview of heavy steel plate, including the grades readily stocked by steel plate suppliers – such as Leeco® Steel – and material testing and processing of heavy plate.

Heavy steel plate is defined as any steel plate material that is 3-inches thick or greater. Heavy plate is comprised of a variety of grades produced in the United States and abroad. These grades are used in various applications, including mining, energy and automotive. However, heavy plate is primarily used in construction and structural applications.

While a wide range of steel plate grades are supplied in heavy thicknesses, the most commonly-requested heavy plate grades are those used in structural or construction applications. These grades – all readily-stocked by Leeco – include ASTM A36, ASTM A572 Grades 42 & 50, ASTM A830 Grade 1020, ASTM A516 Grade 70 and ASTM A514 Grade Q.

Each of these grades contain alloys that enhance the strength and hardness properties desirable in structural and construction applications, which are detailed in the charts below. These properties make the above grades ideal in high-strength applications, regardless of thickness. When thickness increases above 3-inches, however, these grades become ideal for a smaller – but critical – group of applications, such as bridge construction and energy infrastructure.

|

Heavy ASTM Plate Grade |

Carbon |

Manganese |

Phosphorus Max |

Sulfur Max |

Silicon |

|

A36 >2 ½ - 4” thick |

0.27% |

0.85-1.20% |

0.030% |

0.030% |

0.15-0.40% |

|

A36 >4” thick |

0.29% |

0.85-1.20% |

0.030% |

0.030% |

0.15-0.40% |

|

A572 Grade 42 |

0.21% |

1.35% |

0.030% |

0.030% |

0.15-0.40% |

|

A572 Grade 50 |

0.23% |

1.35% |

0.030% |

0.030% |

0.15-0.40% |

|

A830 Grade 1020 |

0.18-0.23% |

0.30-0.60% |

0.030% |

0.030% |

N/A |

|

A516 Grade 70>2” to 4” thick |

0.30% |

0.85-1.20% |

0.025% |

0.025% |

0.15-0.40% |

|

A516 Grade 70 > 4” thick |

0.31% |

0.85-1.20% |

0.025% |

0.025% |

0.15-0.40% |

|

A514 Grade Q |

0.14-0.21% |

0.95-1.30% |

0.030% |

0.030% |

0.15-0.35% |

|

Heavy ASTM Plate Grade |

Yield Point |

Tensile |

|

A36 |

36 ksi |

58-80 ksi |

|

A572 Grade 42 |

42 ksi |

60 ksi |

|

A572 Grade 50 |

50 ksi |

65 ksi |

|

A516 Grade 70 |

38 ksi |

70-90 ksi |

|

A514 Grade Q >2.5” to 6” |

90 ksi |

100-130 ksi |

While less common than the grades above, other steel plate grades may also be supplied in greater thicknesses. These grades can be more difficult to find, but are typically stocked by suppliers with a large inventory of plate products, such as Leeco, and include ASTM A709 and ASTM A829-4140.

While these are also structural steel grades, they are typically used in more specialized applications.

|

Heavy Plate Grade |

Applications |

|

A709 |

Structural steel grade primarily used in the construction of bridges. |

|

A829 Grade 4140 |

Structural steel grade offering greater wear resistance than lower carbon grades of steel. |

The use of heavy plate in structural applications often requires that plate be cut into a variety of shapes and sizes necessary for forming structures. Because of its thickness, heavy plate must be cut using oxy fuel flame cutting. Oxy fuel cutting, which uses a flame and blast of oxygen to heat – and therefore cut – steel plate, is equipped to cut plate with great thicknesses. For example, Leeco’s primary oxy fuel cutting table can cut plate up to 18-inches thick.

Plasma fuel flame cutting is another common process for cutting steel plate. Plasma cutting can make more defined cuts, but it is not capable of cutting plate that is greater than 1.5-inches thick.

As thickness in steel plate material increases, so does the risk for laminations. Laminations are defects caused during the rolling process by the presence of folds, layers, foreign materials or trapped gases. These laminations may also be harder to detect during a visual inspection of thick steel plate and, if left unnoticed, can greatly impair the plate’s structural performance.

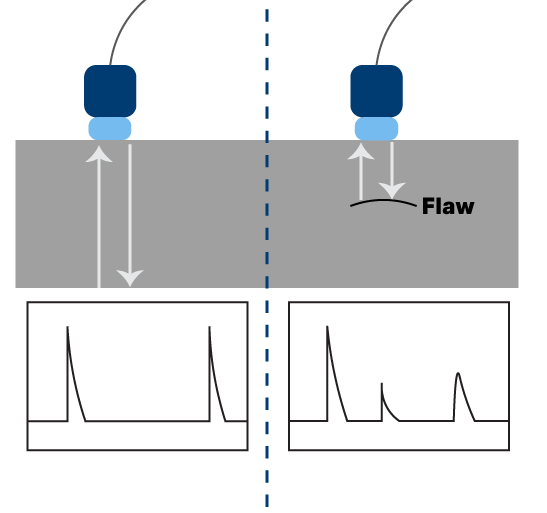

To ensure they are purchasing plate that is safe for use in their projects, heavy steel plate buyers will sometimes request an ultrasonic test (UT). UTs use a probe to send high-frequency soundwaves into the material. When the soundwave hits a barrier, such as a fold, it bounces back to the probe.

These soundwaves are then converted into electrical energy that can be read and analyzed on a test machine’s screen to determine the presence of any major defects that could harm structural integrity.

In addition to UTs, heavy plate buyers may also request other industry-specific material tests, such as the Charpy impact test. The Charpy test measures the ability of steel to absorb impact in a variety of temperature ranges, which is important for ensuring heavy plate used in structural applications within harsh climates can endure extreme, cold temperatures.

Related: Material Testing for Steel

When choosing a supplier for heavy steel plate, it is important to consider a supplier with the following:

With 11 fully-stocked distribution centers across North America and a knowledgeable team dedicated to sourcing heavy plate, Leeco can get you the heavy plate grades you need, when you need them. Leeco also has an ISO 9001 certified quality management system to ensure customers receive quality heavy plate products.

Contact Leeco’s Heavy Plate Division or request a quote today to discuss your heavy plate needs with an experienced sales representative.

Looking for a quote? We recommend you use our quote builder or submit a request for quote document via our RFQ Form.

Quote Builder Submit an RFQ