We use cookies to analyze traffic and improve your experience. We may also share your information with our analytics partners to improve our website, as detailed in our Privacy Policy. You consent to our cookies if you continue to use this website.

When budgeting or estimating a project that requires steel plate or any steel material, it is often challenging to find a ballpark material cost without speaking to a steel supplier. This article looks at the common factors that impact the cost of steel plate, and highlights situations and behaviors that impact price.

Leeco® Steel announces the promotion of Larry Athens to Sales Manager, South region, effective April 1, 2024.

Leeco Steel announces the promotion of Dave Diemel to Vice President of Operations and appointment to Leeco’s executive management team, effective April 1, 2024.

Leeco Steel’s Houston facility reached 10 years accident-free as of January 20, 2024. The facility has been accident-free since its opening.

Leeco Steel announces the promotions of Larry Athens and Gunnar Highland, effective January 1, 2024.

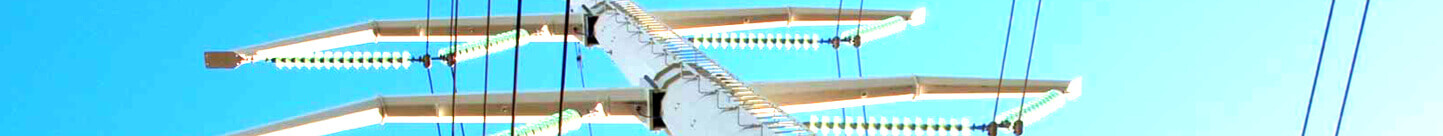

The American wind industry is rapidly growing. Recently passed government legislation provides tax credits and incentives for wind energy projects. This has led to an increase in structural steel plate demand as wind farm projects, both onshore and offshore, get underway. In this article, we will explore the properties and applications of steel plate grades that are commonly used in wind turbines.

Denton Nordhues, President and CEO of Leeco® Steel, shares the market forces he is watching to gauge 2024 steel market outlooks.

Leeco® Steel, the largest supplier of steel plate in North America, announces the promotion of Tom Murray to Sales Manager, North, effective October 1, 2023.

Steel can be foreign or domestic in origin, and project requirements may impact which origin is sourced. Read more to learn about foreign and domestic steel.

Leeco® Steel, the largest supplier of steel plate in North America, announces sales appointments to support its processing business and overall company growth. Andy Polka was appointed to the newly-created role of Director of Processing, and Walt Quinlan was promoted to Director of Sales, North.

Looking for a quote? We recommend you use our quote builder or submit a request for quote document via our RFQ Form.

Quote Builder Submit an RFQ