We use cookies to analyze traffic and improve your experience. We may also share your information with our analytics partners to improve our website, as detailed in our Privacy Policy. You consent to our cookies if you continue to use this website.

"Alexandra Bridge" by tsaiproject is licensed under CC BY 2.0.

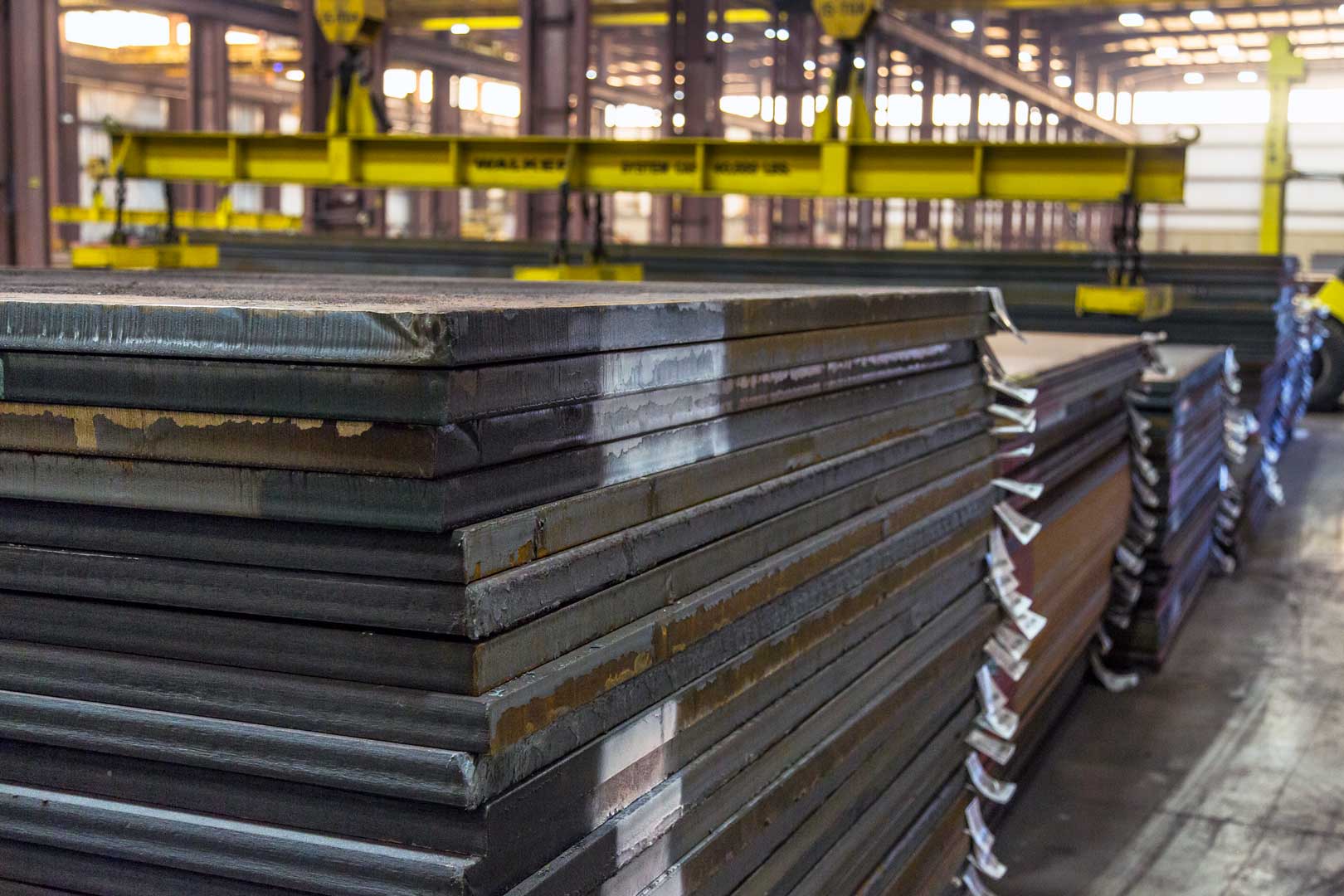

From the buildings we visit, to the homes we live in to the roads we travel, structural steel is a versatile construction material that offers structural strength and fabrication versatility.

This article takes a deeper look at structural steel, its composition, characteristics, uses and more. For information on specific grades of structural steel, browse our high-strength low-alloy structural steel plate page.

Structural steel is a regulated category of steel that must meet industry standards for composition and dimensional tolerances. In the United States, ASTM International specifies and regulates steel grades. Similarly, Canada and Europe have their own regulating bodies and standards. While Leeco® Steel does supply CSA G40.21 steel plate and EN standard steel plate, this article will focus on ASTM standards.

There are a variety of structural steel grades, the most popular being ASTM A36 and ASTM A572. These and other structural steel grades are primarily used to build frames of buildings and bridges. They are also used in the construction of:

According to research published by the American Institute of Steel Construction, structural steel comprised 47% of all construction materials, making it highly likely that any building, bridge or structure you encounter owes some of its design to structural steel.

To fully understand how structural steel differs from non-structural steel, such as steel used in aboveground storage tanks, ships or truck beds, we must first look at structural steel’s composition.

Steel can be produced from recycling old steel, or can be made from raw materials. The process of converting recycled steel into new steel involves melting down existing steel and refining it to fit certain specifications. Producing steel from raw materials is a much longer process.

Steel is an alloy comprised of iron and carbon, both of which are abundant, but rarely found in pure form. To produce steel from raw materials, iron is extracted from iron ore, which is rich in iron oxides. In the United States, the majority of iron ore is extracted from taconite, which is found in abundance in Minnesota. The extraction process grinds taconite into a sandy composition, and uses magnets to separate iron ore (in the form of magnetite) from other minerals and substances.

While iron is typically thought of as being hard and strong, raw iron ore is actually soft enough to cut with a knife and some muscle. It is the addition of carbon that gives iron-based alloys their strength.

The most common way of producing an iron-carbon alloy is by mixing coke, a carbon-rich form of coal, with iron ore and applying heat until the coke ignites. This intense heating causes coke to drop carbons and bond to oxygens from the iron oxides, leaving a mixture of iron and carbon. This process known as reduction.

After reduction, the material contains about 4% carbon. It then undergoes additional heating and cooling processes to reduce the amount of carbon, making the material harder and stronger. The material becomes steel once the carbon content falls below 2.1% of the material’s weight. To produce structural steel, carbon must be further reduced until its composition is only 0.05-0.25%.

The end result is structural steel, which boasts a high strength-to-weight ratio, is 100% recyclable and economically priced. There are many grades of structural steel, all of which differ slightly in composition. These compositions play a major role in determining the material needed for any given project.

Alternatively, the steel can be further processed – through additional heating and cooling treatments and/or the addition of alloys such as chromium, molybdenum and titanium – to increase hardness. These processes impact overall brittleness, in most cases, making the resulting material not ideal for structural use.

Below is the composition of two popular grades of structural steel: ASTM A36 and ASTM 572. Other structural steel grades have similar compositions, but may also have additional alloys or have underwent further processing.

| Grade | Carbon | Manganese | Phosphorus Max | Sulfur Max | Silicon |

|---|---|---|---|---|---|

| A36 | 0.25-0.29% | 0.80-1.20% | 0.030% | 0.030% | 0.15-0.40% |

| A572 | 0.21-0.26% | 1.35-1.65% | 0.030% | 0.030% | 0.15-0.40% |

| A514* | 0.10-0.21% | 0.40-1.50% | 0.15-0.80% |

*A514 also contains chromium, molybdenum, titanium, vanadium and boron.

The primary difference in composition between structural and non-structural steel is the presence of additional alloys that increase hardness, but also increase brittleness. In some cases, the additional alloys still produce structural-grade steel, but in other cases, the steel produced is too brittle to be used in structural capacities.

Outside of chemical composition, yield and tensile strengths help determine the steel grade and overall application.

Yield strength is the maximum point of stress at which material will change shape permanently. For example, when jumping off a diving board, the board naturally bends to absorb your weight and energy, but once you leap from the board, the board will return to its original shape.

The board’s yield strength would be the point where it bends under weight and energy, and remains permanently bent even after the diver launches.

Yield is an important characteristic of structural steel, which must have some give to absorb weight. In bridges, for example, the yield strength is the maximum weight the bridge can withstand before undergoing permanent damage.

Tensile strength is the point at which bent material will break. In our diving board example, this is the weight and energy it would take to snap the board.

Elongation is the percent the length of a stretched material increases before it breaks. In our diving board example, this would be the percent the board's length increases before snapping. Elongation is used to measure ductility, or the capability of a material to be stretched out before it becomes weak or brittle.

Below is a chart that shows the yield and tensile points of three types of common structural steel. These points are measured in pounds per square inch (“psi”) or kilopounds per square inch (“ksi”), as shown below. They are also sometimes referenced in megapascals.

| Grade | Yield Point | Tensile Point |

|---|---|---|

| A36 | 36 ksi | 58-80 ksi |

| A572-50 | 50 ksi | 65 ksi |

| A514 | 90-100 ksi* | 100-130 ksi* |

*Yield point and tensile strength for ASTM A514 are dependent on thickness

These metrics are critical to engineers as they plan the material needed for a particular project.

Especially important in structures is their ability to absorb energy. Brittle materials can only absorb a low amount of energy before fracturing or failing. Structural steel combines strength with ductility, allowing it to absorb great amounts of energy before failing.

The Charpy impact test – named after Georges Charpy, who standardized impact testing – uses a heavy hammer pendulum to measure the amount of energy a type of steel can absorb. The test goes a step further and tests impacts at varying temperatures. This is important for steel-based structures that are outdoors in extreme temperatures.

Charpy tests are quite common for structural steel projects. A small sample of the steel – known as a coupon – is cut out of the master plate and taken to an independent lab for testing. The results tell engineers if the material is adequate for their project.

When choosing raw materials for building construction, engineers often consider factors such as strength and constructability. With its strength, machinability and ductility, structural steel is one of the most common materials used in commercial and industrial building construction.

High tensile points and the addition of strengthening alloys ensure structural steel pieces are strong enough to withstand a building’s stress without breaking. Skyscrapers, for example, are often constructed from structural steel due to the material’s strength. In comparison to other common building construction materials, such as concrete, steel is a strong – but relatively lighter – material used for constructing tall building frames.

Structural steel’s machinability allows building constructors to weld or bolt the material into a variety of shapes. Two common applications of steel used in building construction are structural sections, which account for about 25% of the steel used in buildings, and reinforcing bars, which account for about 44% of the steel used in buildings.

In areas prone to earthquakes, ductility is an important structural steel property in materials used for building construction. High ductility allows structural steel frames to stretch and move under the stress from an earthquake, making the building less prone to suffering devasting structural damage.

Charpy testing building construction steel plate is important for structures built in cold environments, as this test ensures the steel is tough enough to withstand extremely cold temperatures without fracturing or breaking.

With their relatively high tensile points, ductility and presence of alloys that increase strength and machinability, A36 and A572 are two structural steel grades typically used in building construction.

Structural steel is the skeleton of our infrastructure, and we rely on its strength, longevity and durability every day. Leeco Steel supplies bulk quantities of many grades of structural steel plate to companies across the country and around the globe. Browse and receive a quote on our structural steel plate offerings, or contact a Leeco expert today to place an order.

Additionally, current Leeco Steel customers who are ready to buy A36, A572 and other structural steel plate grades can place an order on Leeco Pro, our ecommerce website. Using Leeco Pro simplifies the procurement process and allows you to buy the plate you need in just a few clicks. Learn more and buy structural steel plate grades online.

Looking for a quote? We recommend you use our quote builder or submit a request for quote document via our RFQ Form.

Quote Builder Submit an RFQ